lv switchgear commissioning | mv switchgear inspection lv switchgear commissioning Major inspection should be scheduled for power plant shutdowns and concentrate for low voltage switchboards on identifying contact wear, correct operation of interlocks, correct overload settings and fuse sizes, signs of overheating, and undue dirt or corrosion.

10 talking about this

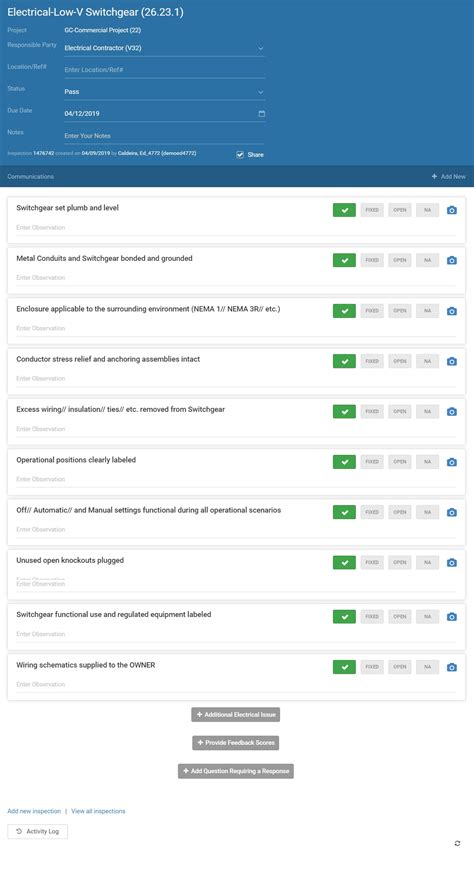

0 · switchgear maintenance checklist

1 · switchgear inspection requirements

2 · switchgear inspection checklist

3 · mv switchgear inspection

4 · lv inspection procedures

Dan's Tax Lv is in the Tax Return Preparation Services business. View competitors, revenue, employees, website and phone number.

The commissioning process for low voltage switchgear and circuit breakers involves evaluations, verifications, and checks that determine whether the proper switchgear and circuit breaker specifications and installation requirements are met.

Major inspection should be scheduled for power plant shutdowns and concentrate .This article continues the series of articles dedicated to the erection, testing and .Under commissioning, we assume various activities related to testing, verifications, .

The commissioning process for low voltage switchgear and circuit breakers involves evaluations, verifications, and checks that determine whether the proper switchgear and circuit breaker specifications and installation requirements are met.

Major inspection should be scheduled for power plant shutdowns and concentrate for low voltage switchboards on identifying contact wear, correct operation of interlocks, correct overload settings and fuse sizes, signs of overheating, and undue dirt or corrosion. This article continues the series of articles dedicated to the erection, testing and commissioning of MV/HV switchgear by describing the most important precautions and recommendations in various procedures and steps. Count on ABB's expertise for safe and correct installation and commissioning of your switchgear, ensuring high reliability and optimum life-cycle performance.

Inspection, Testing and Commissioning of Electrical Switchboards, Circuit Breakers, Protective Relays, Cables and PLCs. THIS BOOK WAS DEVELOPED BY IDC TECHNOLOGIES. WHO ARE WE? IDC Technologies is internationally acknowledged as the premier provider of practical, technical training for engineers and technicians.Low Voltage Switchgear Service. Installation and Commissioning. Correct installation and commissioning will ensure a high degree of operational reliability. To achieve a problem-free start up, it is required that ABB installation and commissioning procedures are followed. We provide comprehensive installation and commissioning services.

R&B Switchgear Group offer expert installation and commissioning services for low voltage (LV) and high voltage (HV) switchgear and associated assets.

Power – Low Voltage Switchgear MNS-R Erection, commissioning, operation and maintenance Service Manual Indice 1 Technical Description 6 2 Packing and Transport 17 3 Erection 19 4 Start up and Operation 38 5 Maintenance and Spare Parts 44 Switchgear Testing and Commissioning Procedure. Busbar Torque Test: After installation of the switchboards, all the bus bar bolts are torque tested as per manufacturer’s recommendations by using a calibrated torque wrench. Breaker to Breaker Resistance Test. Under commissioning, we assume various activities related to testing, verifications, approvals, consents, and similar, by which LV switchgear (or any other equipment) is gradually submitted for use to the employer by the contractor. The commissioning process for low voltage switchgear and circuit breakers involves evaluations, verifications, and checks that determine whether the proper switchgear and circuit breaker specifications and installation requirements are met.

Major inspection should be scheduled for power plant shutdowns and concentrate for low voltage switchboards on identifying contact wear, correct operation of interlocks, correct overload settings and fuse sizes, signs of overheating, and undue dirt or corrosion.

switchgear maintenance checklist

This article continues the series of articles dedicated to the erection, testing and commissioning of MV/HV switchgear by describing the most important precautions and recommendations in various procedures and steps.

Count on ABB's expertise for safe and correct installation and commissioning of your switchgear, ensuring high reliability and optimum life-cycle performance.Inspection, Testing and Commissioning of Electrical Switchboards, Circuit Breakers, Protective Relays, Cables and PLCs. THIS BOOK WAS DEVELOPED BY IDC TECHNOLOGIES. WHO ARE WE? IDC Technologies is internationally acknowledged as the premier provider of practical, technical training for engineers and technicians.Low Voltage Switchgear Service. Installation and Commissioning. Correct installation and commissioning will ensure a high degree of operational reliability. To achieve a problem-free start up, it is required that ABB installation and commissioning procedures are followed. We provide comprehensive installation and commissioning services.

R&B Switchgear Group offer expert installation and commissioning services for low voltage (LV) and high voltage (HV) switchgear and associated assets.

Power – Low Voltage Switchgear MNS-R Erection, commissioning, operation and maintenance Service Manual Indice 1 Technical Description 6 2 Packing and Transport 17 3 Erection 19 4 Start up and Operation 38 5 Maintenance and Spare Parts 44 Switchgear Testing and Commissioning Procedure. Busbar Torque Test: After installation of the switchboards, all the bus bar bolts are torque tested as per manufacturer’s recommendations by using a calibrated torque wrench. Breaker to Breaker Resistance Test.

switchgear inspection requirements

Lenovo Legion 7 16IRX9 Glacier White, 16" 3.2K 165Hz G-SYNC, Core i7-14700HX, 16GB, 1TB SSD, GeForce RTX 4060 8GB (DLSS 3), Windows 11 Pro

lv switchgear commissioning|mv switchgear inspection